Original Author: Coral Hwang

At a special time, many large exhibitions have to cancel or delay. Without personal visiting, as a Supplier of Textile Ink, we would love to share with you which new print heads become the mainstream in China digital textile and industrial printing market. Let us get started and see what is the difference between those new heads.

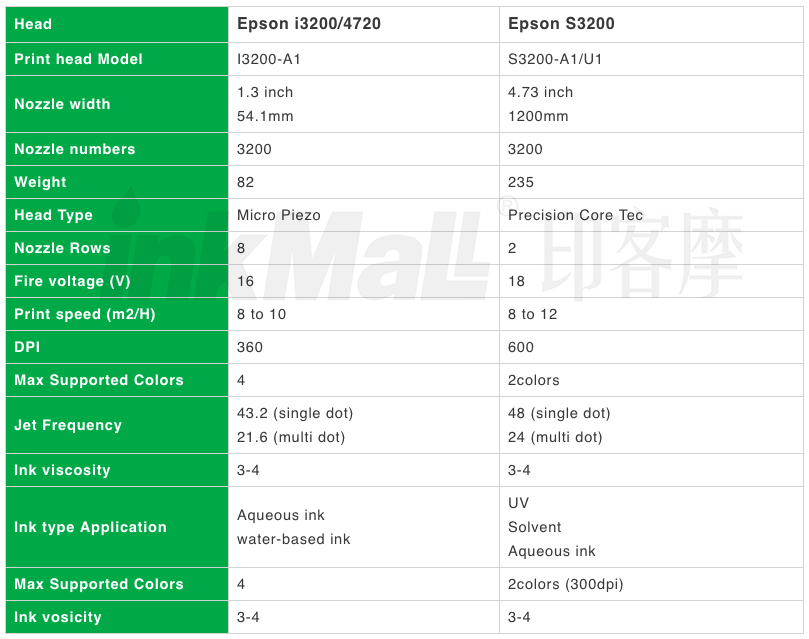

Appearance and parameter

The specific models are S3200 A1 and I3200 A1, 4720 print head, first let's take a look at the appearance of the three print heads. From the aspect of appearance, we can clearly see the difference between the S3200 print head and the I3200 print head.

* all data only reference to 2020 released info, it does not indicate the final performance in the future

Talk about the textile print head, we have to mentioned Epson 5113. Another non-easy identified sublimation print head from appearance, specifications, and performance. What’s more, since 5113 head stopped production, and locked head on market. but due to the economical price and availability, Epson i3200/4720 had gained a lot of customers' favorites.

Compare 1: Epson I3200 and 4720

Epson I3200 and 4720 not only very similar in appearance, but also in performance. The 4720 nozzle is not officially on sale. It is the dismantled nozzle of the desktop printer.

1.1 From product parameters

In January 2020, Epson introduced the I3200-A1 print head, it’s the Epson authorized 3200 print head, this head no longer use with the decryption card as 4720 head, print head accuracy, and lifespan is 20-30% higher than the previous 4720 print head.

The ink dot of the I3200 print head is more delicate than the disassembled print head 4720. The frequency that can be reached is also faster, and the actual printing speed is faster than that of 4720.

1.2 Application

I3200 print head in durability and stability due to the targeted board matching and strict quality control. The 4720 is not great options for printing with oil based printer ink.

So when you buying 4720 print head or a machine with 4720 head, please pay attention about the print head equipping, with old 4720 head or the I3200-A1 head.

Compare2: Epson I3200 and S3200

* all data only reference to 2020 released infor, it does not indicate their final performance in the future

2.1: Printing Accuracy and Nozzle width

Although the two print heads are positioned as industrial print heads, the S3200 the print head is obviously larger in size.

S3200 Print head is 4 inches and the I3200 nozzle is 1 inch.

Which means, 1 unit S3200=3.6 unit I3200

In terms of colors, the S3200 nozzle is a two-color nozzle and the I3200 the nozzle is a four-color nozzle. The frequency of S3200 is also faster, and the smallest droplet volume is smaller.

2.2: Basic Cost

1 unit S3200=10unit I3200 Head

Compare the size and speed accuracy, S3200 nozzles are more advantageous than I3200 nozzles. However, considering the cost and durability, and stability of the nozzle, more and more new machines are equipped with the official I3200 nozzle

Different types of ink

In the current digital printing market. Ink can be defined in three types: water-based ink, eco-solvent ink, and UV ink. For water-based ink, S3200, Kyocera, Brother 1680, and I3200 all have good responses. The 4720 nozzles are still the largest in the market and are widely used in the textile and advertising fields. For oil-based ink, Ricoh G6, Toshiba CJ1, Konica 1024a have a good reputation

For industrial compatibility, Epson I3200, Ricoh G6, Toshiba CJ1, Brother 1680, Konica 1024a, and other small-sized print heads are generally used in small-format economic equipment. The large-size print heads such as S3200 and Kyocera is generally used for large format and high-speed industrial-grade equipment.

Estimated Printing Cost-effectiveness

There are already many manufacturers in the market promoting the four-head or eight-head S3200 machine solution.

*All data is regarding the current most used solution, will change without prior notification.

From the product positioning point of view, the S3200 print head is positioned in the high-end customer group. I3200 is positioned at the middle and low-end customer groups, and the price difference between the two is also very large. If it can combine durability, stability, printing speed in a better cost-effective way. It should be the future trend for the high-end market

Thanks for watching. Follow us, we would love to share more details and information about the inkjet industry and help our dealers make a profit.

Comments

Post a Comment